In the world of mechanical engineering, every component must be flawlessly assembled for systems to run smoothly.

One of the most fundamental yet crucial tasks is the assembly and adjustment of chains used in gear systems.

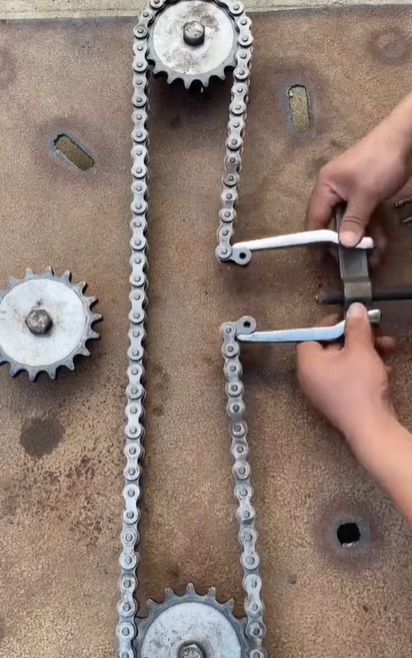

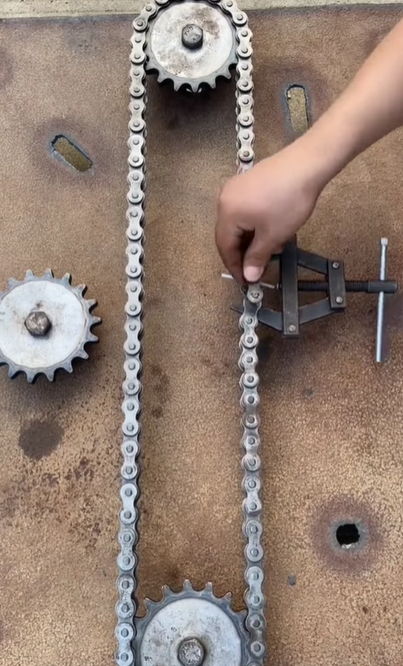

Using specialized tools, technicians meticulously align and secure chain links to ensure they fit tightly around sprockets.

This precise work prevents slippage and ensures longevity in machinery from bicycles to industrial conveyors.

Breaking Down the Process: Chain Link Tools

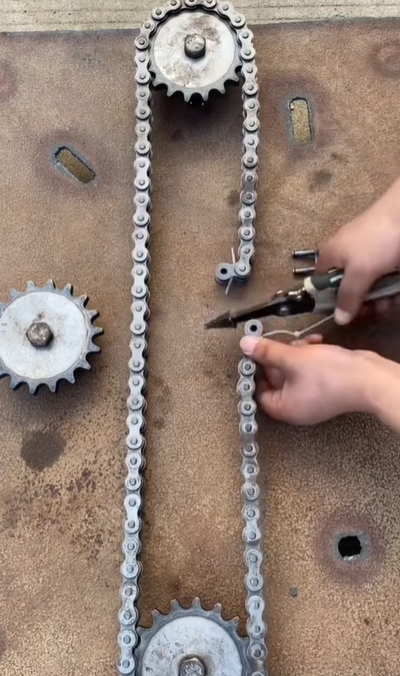

To adjust a chain, tools like chain breakers, pliers, and alignment devices are employed.

These tools allow for both the removal and reconnection of chain links, adapting the chain length to the specific requirements of the machine.

It’s a hands-on demonstration of how small tools can tackle big mechanical problems efficiently.

Cutting Through the Toughest Materials: Grinding Mastery

Metal grinding is another critical process where machines truly shine.

A grinder, with its high-speed rotating disc, can cut through rusted bolts or tough materials that human hands could never manage.

Sparks fly as the grinder makes short work of stubborn metal, preparing surfaces for further work or restoring functionality to aged equipment.

The Art of Extraction: Removing Broken Bolts

When bolts break and become stuck inside machinery, specialized extractors come into play.

After grinding the surface to expose the broken bolt, a spiral extractor is used to grip and twist the bolt out, saving the component from being discarded.

This process showcases the ingenuity behind tool design, allowing repairs that extend the life of costly equipment.

When Machines Meet Craftsmanship

These tools and machines do more than just fix—they innovate.

Whether it’s connecting chains with perfect tension or rescuing a bolt embedded in rust, they exemplify how human ingenuity paired with the right equipment can overcome challenges in manufacturing, repair, and maintenance.

Tools That Keep the World Moving

From workshops to factories, these simple yet powerful machines are essential.

They save time, reduce waste, and enable precision that manual labor alone can’t achieve.

Watching them in action is not only satisfying but also a reminder of the brilliance in everyday engineering.