In the world of heavy machinery and industrial maintenance, proper lubrication is the key to longevity and efficiency.

Grease, a thick, oily substance, reduces friction, prevents wear, and protects metal surfaces from rust and corrosion.

This article takes you through the process of how grease is prepared and loaded into a dispensing system.

Gathering the Essential Grease

The process begins by dipping a grease container into a large tub filled with thick, golden-brown lubricant.

The technician ensures that the container is filled completely, minimizing air pockets, which can interfere with effective lubrication.

Preparing for Dispensing

After filling the container, the excess grease is carefully smoothed out.

This step is crucial to ensure a clean fit into the dispensing equipment and to avoid wastage during the loading process.

Sealing the Container

Once filled, the grease container is sealed tightly.

The technician checks for any gaps or leaks to maintain pressure integrity.

A tight seal ensures that the grease can be dispensed smoothly without clogging or air disruption.

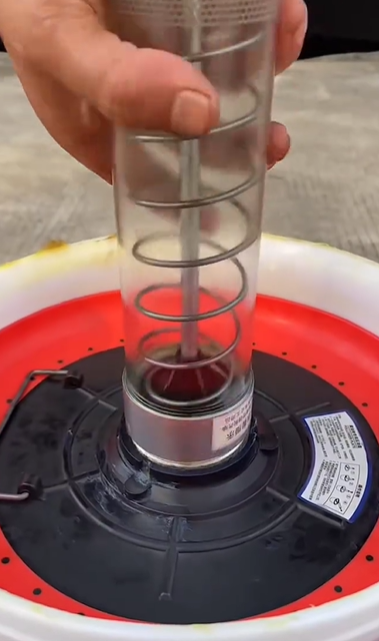

Placing into the Dispensing Unit

With the container ready, it’s inserted into the central hub of a larger grease dispensing system.

The red and black sealing mechanism locks it in place securely, setting the stage for controlled dispensing during machine lubrication.

Ensuring Flow Efficiency

The final step involves compressing the spring-loaded mechanism that pushes the grease through the system.

This ensures a consistent flow rate when the grease is applied to various mechanical parts, keeping machines running efficiently.

Grease—The Silent Protector of Machines

While it may seem like a simple task, grease loading is an essential part of keeping machinery operational.

Without proper lubrication, wear and tear can quickly lead to costly repairs.

This behind-the-scenes look shows how carefully technicians prepare and use grease in industrial environments.